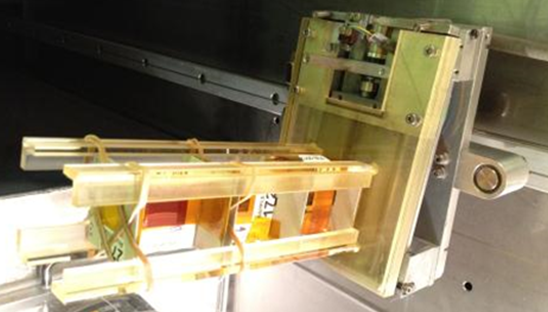

Shuttle

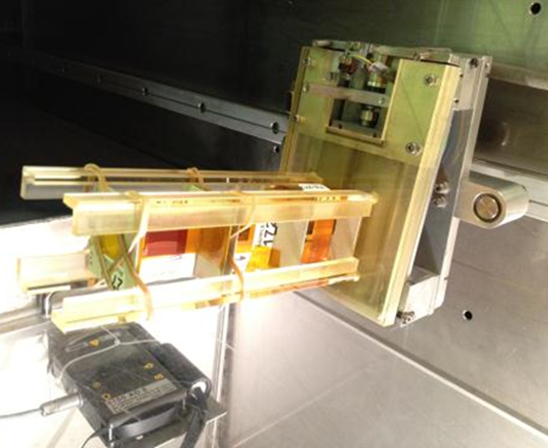

The shuttle (named IRRAD1) is a remote-controlled conveyor travelling on a rail system that allows the positioning of “small” objects in the beam (typically silicon detector test-samples) without the need of human access into the area. This system guarantees a precise X-Y alignment of ±0.1mm with respect to the beam axis and it is mainly designed for the irradiation of passive samples at RT.

Full description:

On the shuttle, the maximum volume available for irradiation is of about 50×50×200mm3 for a maximum weight of about 1Kg. The standard size of the beam spot on the shuttle system (σ) is of about 5-7mm RMS but it can vary according to the different beam focusing options (see section 3.4). In particular, focusing on the shuttle system, the spot size can be reduced further down during high-intensity irradiation periods.

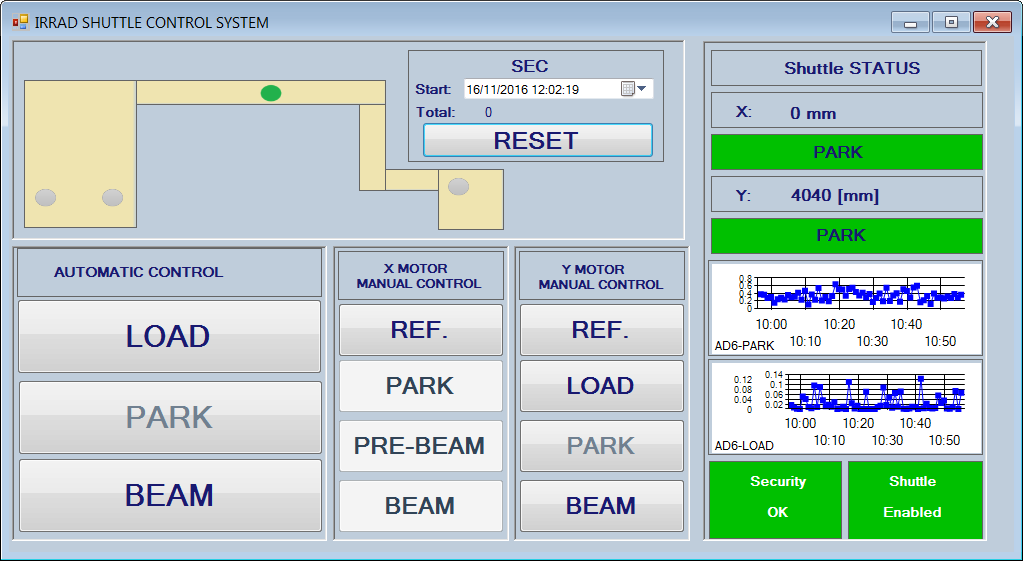

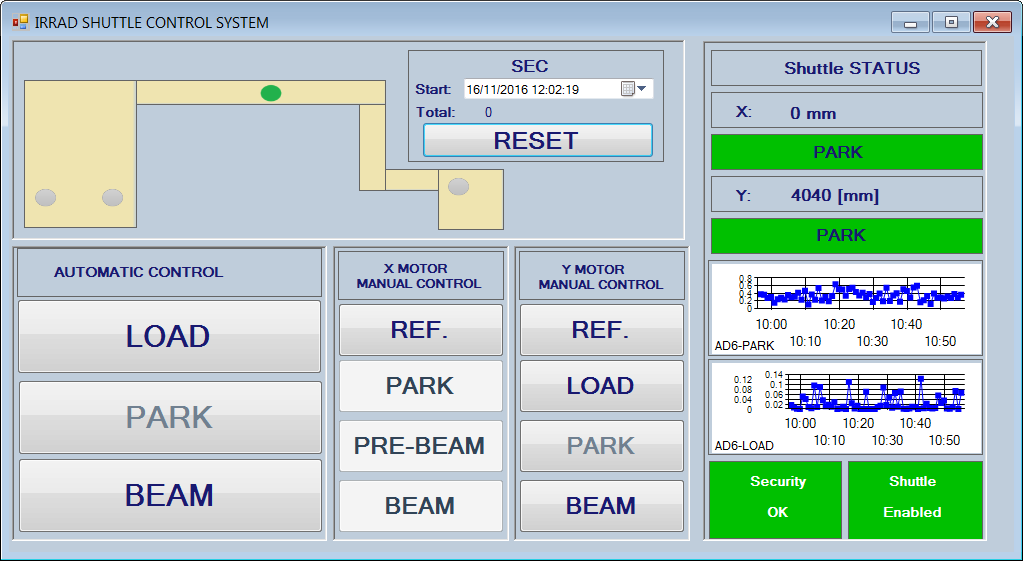

The shuttle control system interface provides to the user the location of the shuttle on the horizontal and vertical axis. The user can choose to move the shuttle in beam, leave the samples cool down in a safe intermediate position or remove the samples out of the shuttle if this is allowed by the radiation dosimetry. The main functionalities include: